The price of gas is the most obvious driver of energy bills, but one driver that is often overlooked is boiler efficiency. Inefficient boilers can cost residents over £500 more per year.

On paper, boilers perform at around 90-91% efficiency, but field trials repeatedly show that performance in the home is often much worse. A 2009 trial by the Energy Saving Trust found that boilers perform on average at only 82.5% efficiency, with some boilers performing as low as 68.6% efficiency.

Guru Systems monitors gas boilers using Guru Heat Smart, and we’ve seen the same results. Boilers that are expected to perform at around 90% efficiency often only reach efficiencies in the low 70s.

Inefficient boilers cost residents

The price cap which protects customers who heat their homes using gas boilers had already risen by 12% in October, and will rise again by an unprecedented 54% from April.

It’s possible to see the impact of boiler inefficiency on prepayment customers by comparing the price to heat a home at different efficiency levels.

To demonstrate the impact of inefficiency on price, we’ve used Ofgem’s figure of £983 for the average annual gas bill and assumed that the boiler is older (see graphs below), so only performing at 88% efficiency. The cost of energy then rises as efficiency decreases because gas is wasted to achieve the same level of comfort in the home. This is a hypothetical scenario, but the impact on annual bills is clear – a boiler working at 75% efficiency is £171 more expensive to run than a boiler working at 88% efficiency.

| Boiler efficiency | Spending on gas to reach the same level of comfort in the home* |

|---|---|

| 88% | £983 |

| 85% | £1,018 |

| 80% | £1,081 |

| 75% | £1,154 |

Act before the next heating season

While many local authorities and housing associations are beginning to plan to replace gas boilers with heat pumps, the cost and carbon savings associated with this change won’t be realised in time for the next heating season.

To protect residents from price rises (as well as reducing carbon emissions), the aim must be to ensure that gas boilers perform as well as they can until they are replaced.

With proper monitoring and subsequent interventions, gas boilers can perform better ahead of next year’s heating season – something that will disproportionately benefit the poorest households.

Boiler inefficiency is often caused by high return temperatures

Boilers cannot condense when the temperature flowing back from the radiators to the boiler is too high. This can happen when radiators aren’t balanced, or when the thermostat or boiler settings aren’t at the right level – problems that are often easy to solve.

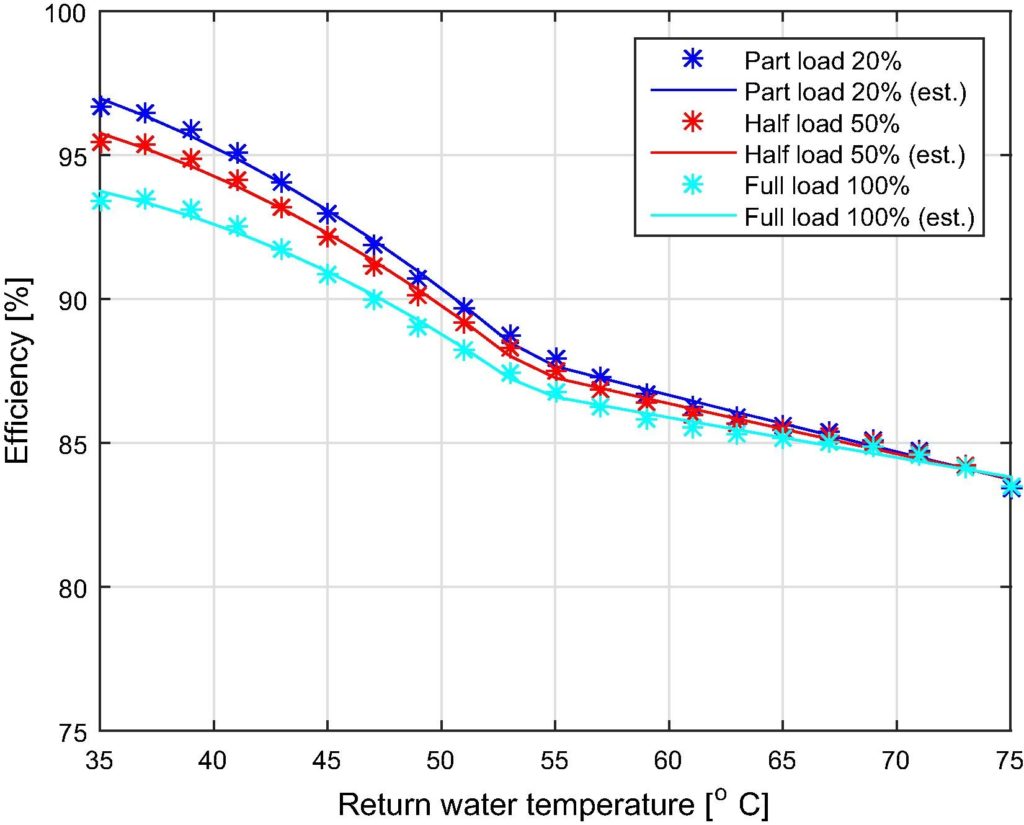

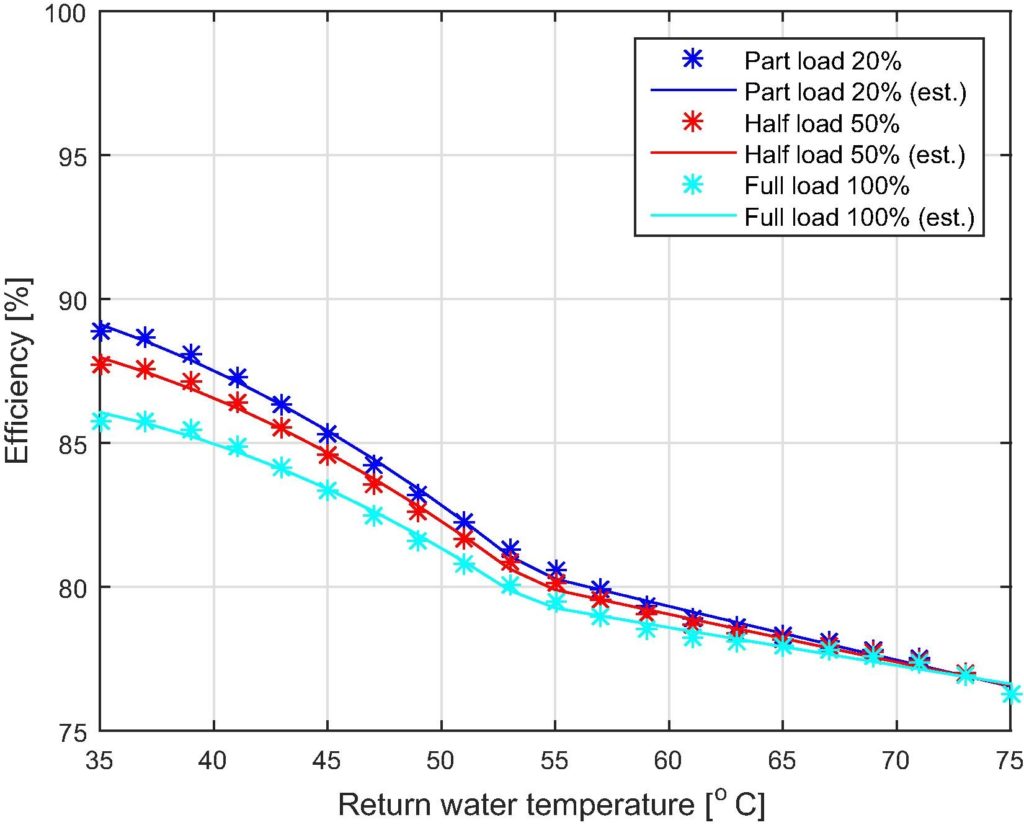

These two graphs show how efficient a domestic boiler can be at different return temperatures. The graph on the left shows a standard boiler, and the graph on the right shows an older boiler.

| Efficiency curve when the boiler is new | Efficiency curve when the boiler is degraded |

|---|---|

|

|

Source: Real-time monitoring energy efficiency and performance degradation of condensing boilers, by Simone Baldi et al. (2017)

You can’t manage what you don’t measure

Most local authorities and housing associations don’t yet have visibility or control over their boiler fleet – this is why we created Guru Heat Smart.

Guru Heat Smart allows property managers to monitor and remotely control individual gas boilers (or heat pumps). The accompanying software displays performance data, ambient temperature and humidity data to help predict the risk of mould growth.

The Guru Heat Smart device captures detailed performance data from the heating system, including return temperatures from radiators, to help identify and resolve performance issues, and reduce maintenance callouts.

Here’s an example of what gas boiler performance looks like on the Guru Heat Smart web platform:

Data from this boiler shows that the difference between the flow temperature (orange) and return temperature (yellow) is almost non-existent. In practical terms this low Delta T means that very hot water is rushing around the heating systems only imparting a small amount of useful heat to the dwelling via the radiators on each loop.

It also shows that the boiler regularly receives water with return temperatures of over 70°C. When water returns from radiators to the boiler this hot, the boiler can’t condense properly. In this situation the resident is paying too much for their heat to achieve the same level of comfort in their home.

This cost difference may be enough to push households into fuel poverty, especially when prices are high. It also means unnecessary carbon emissions.

Data-led interventions

Performance data means that problems can be identified, and the appropriate interventions can be made. There a number of interventions that could be made ahead of the next heating season, including:

- Installation of flow limiting Thermostatic Radiator Valves (TRVs)

- Reducing the flow temperature of the boiler, especially outside of peak heating season

- Rebalancing radiators using existing radiator valves to reduce return temperatures

- Improve boiler, cylinder or heating pipework insulation

- Improving radiator sizing

- Make sure replacement boilers are appropriately sized

Data on how a resident is heating (or not heating) their home may also be useful for resident liaison teams. Data may help guide conversations around fuel bills or fuel poverty.

Underheating and mould growth

Not only are high fuel bills difficult for many residents, but when a house is cold and poorly ventilated, the risk of mould growth is much higher.

Guru Heat Smart captures ambient temperature and humidity data to help predict the risk of mould growth. This information, when viewed alongside boiler performance, can help local authorities and housing associations to support vulnerable customers in a more holistic way.

Better performing boilers use less fuel..

.. and less fuel means lower resident fuel bills.

If you’re interested in learning more about how to improve gas boiler performance, please contact our Sales team via sales@gurusystems.com or 020 8050 4305.